General information

Material information

Connection data-IEC

Connection data-UL

Environment & Safety

UL Recognized

CUL Recognized

VDE Approval

-

General information

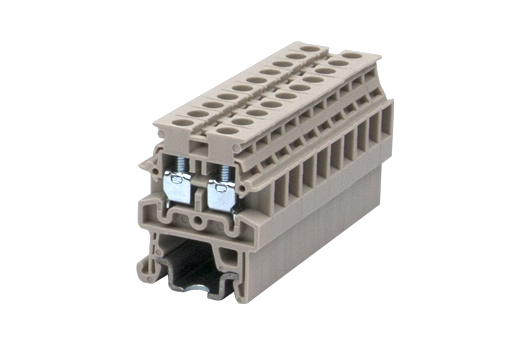

- Short description

- DIN rail terminal blocks, Feed through terminal blocks

- Long description

- Feed through terminal blocks, Screw Connection, Width:5.1mm, M2.5, 300V, 20A

- Category

- Feed through terminal blocks

- Color

- Beige (default)

- Connection method

- Screw connection

- Type of locking

- Rail mounting

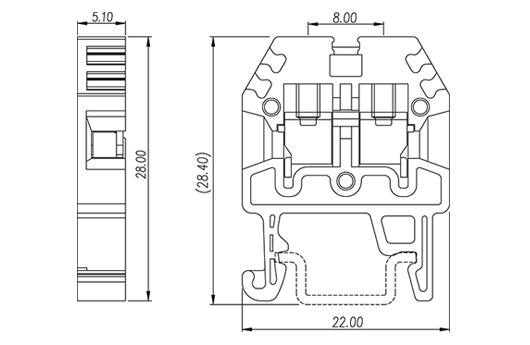

- Length (mm)

- 22

- Width (mm)

- 5.1

- Height (mm)

- 28

- Number of positions

- ≥1P

- Level

- Single level

- Connection points

- 2

-

Material information

- Insulation material

- PA

- Insulation material group

- I

- Flame retardant rating , compliant with UL94

- V0

- Insulation resistance

- ≥500MΩ at DC 500V

-

Connection data-IEC

- Rated voltage (V)

- 500

- Rated current (A)

- 24

- Rated voltage (III/3)(V)

- 500

- Rated impulse voltage (II/2)(KV)

- 4

- Rated impulse voltage (III/2)(KV)

- 4

- Rated impulse voltage (III/3)(KV)

- 4

- Conductor cross section solid. min (mm²)

- 0.34

- Conductor cross section solid.max (mm²)

- 2.5

- Conductor cross section stranded. min (mm²)

- 0.34

- Conductor cross section stranded. max (mm²)

- 2.5

- Conductor cross section flexible, with min ferrule without plastic sleeve (mm²)

- 0.34

- Conductor cross section flexible, with max ferrule without plastic sleeve (mm²)

- 1.5

- Conductor cross section flexible, with min ferrule with plastic sleeve (mm²)

- 0.34

- Conductor cross section flexible, with max ferrule with plastic sleeve (mm²)

- 1.5

- 2 conductors with same cross section, solid, min (mm²)

- 0.34

- 2 conductors with same cross section, solid, max (mm²)

- 1

- 2 conductors with same cross section, stranded, min (mm²)

- 0.34

- 2 conductors with same cross section, stranded, max (mm²)

- 1

- 2 conductors with same cross section flexible, with min ferrule without plastic sleeve (mm²)

- 0.5

- 2 conductors with same cross section flexible, with max ferrule without plastic sleeve (mm²)

- 0.75

- 2 conductors with same cross section flexible, min twin ferrules with plastic sleeve (mm²)

- 0.5

- 2 conductors with same cross section flexible, max twin ferrules with plastic sleeve (mm²)

- 0.75

- Screw thread

- M2.5

- Slotted screwdriver size (Blade thickness x Width)(mm)

- 0.6x3.5

- Philips screwdriver size

- PH1

- Rated torque (N.m)

- 0.4

- Stripping Length (mm)

- 7~9

- Mounting rail

- TS-15

- End cover plate required

- YES

- Grounding connections

- NO

-

Connection data-UL

- Rated voltage (UL/CUL Group B)(V)

- 300

- Rated current (UL/CUL Group B)(A)

- 20

- Rated voltage (UL/CUL Group C)(V)

- 300

- Rated current (UL/CUL Group C)(A)

- 20

- Rated voltage (UL/CUL Group D)(V)

- 300

- Rated current (UL/CUL Group D)(A)

- 10

- Min. solid wire connection (AWG) acc. to UL/CUL

- 22

- Max. solid wire connection AWG acc. to UL/CUL

- 12

- Min. stranded wire connection AWG acc. to UL/CUL

- 22

- Max. stranded wire connection AWG acc. to UL/CUL

- 12

-

Environment & Safety

- Back of the hand protection (YES or NO)

- YES

- Finger protection (YES or NO)

- YES

- Operating temperature. max (°C)

- 120

- Operating temperature. min (°C)

- -40

-

UL Recognized

- Wire Range (Group B)(AWG)

- 22~12

- Rated voltage (Group B)(V)

- 300

- Rated current (Group B)(A)

- 20

- Wire Range (Group C)(AWG)

- 22~12

- Rated voltage (Group C)(V)

- 300

- Rated current (Group C)(A)

- 20

- Wire Range (Group D)(AWG)

- 22~12

- Rated voltage (Group D)(V)

- 300

- Rated current (Group D)(A)

- 10

-

CUL Recognized

- Wire Range (Group B)(AWG)

- 22~12

- Rated voltage (Group B)(V)

- 300

- Rated current (Group B)(A)

- 20

- Wire Range (Group C)(AWG)

- 22~12

- Rated voltage (Group C)(V)

- 300

- Rated current (Group C)(A)

- 20

- Wire Ranget (Group D)(AWG)

- 22~12

- Rated voltage (Group D)(V)

- 300

- Rated current (Group D)(A)

- 10

-

VDE Approval

- Wire Range (mm²)

- 0.34~2.5

- Rated voltage (V)

- 500

- Rated current (A)

- 24

-

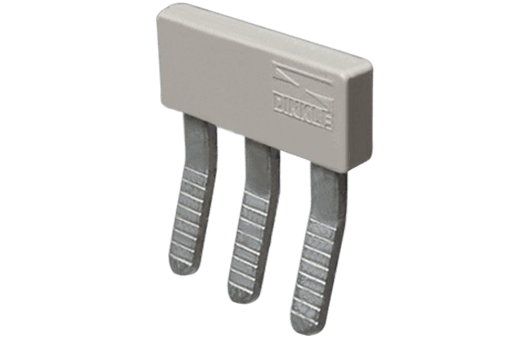

CSC-2.5XXPS

Insertion Bridge For DK2.5S, PM2.5N-XXP, DK2.5P.

Beige color.

Using UL94-V0 class of insulation material. - Add

-

TM42LW

Marking Label For

BEST APPLICATION:

DP2.5N Series, DP2.5N-3L-SPE, DPH2.5 Series, AK2.5 Series, DKES1.5N2, DKES1.5N3, DPP2.5N Series, DP2.5N-3L, DP2.5N-3L-PV, DP2.5N-3L-L3PE, DP2.5N-3L-PE, DPH1.5SGU, DK2.5S, DK1.5SG Series, PM2.5N-XXP, PM2.5WN-XXP, PMM2.5WN-XXP, AKK2.5, AKK2.5-PV, AKK2.5-PE, AKK2.5-D Series, DK2.5L-3L, DK2.5P

AVAILABLE APPLICATION:

DPES2.5, DPES2.5-PE, DP2.5PG, DP2.5SG Series, DPPES2.5, DPPES2.5-PE

White color.

Using UL94-V0 class of insulation material. - Add

-

TS-15

DIN-Rail For DK..S series.

Material is iron.

Length of 1000mm / 2000mm. - Add

-

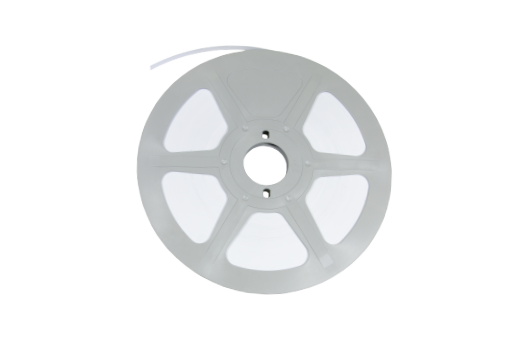

TM-R100

Continuous Flat Marking Labels - Add

-

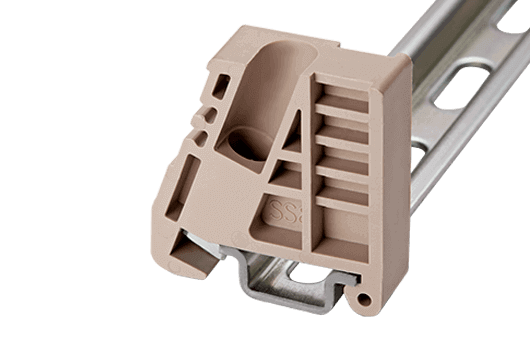

SS8

End Bracket For TS-15 rail.

Beige color.

Using UL94-V0 class of insulation material. - Add

-

DK2.5PC

End Cover For DK2.5S

Beige color.

Using UL94-V0 class of insulation material. - Add

The web catalog is for reference only. Dinkle remains the right of product modification and engineering change of the design. The final product is made according to engineering drawing.