- Informazioni generali

- Descrizione breve

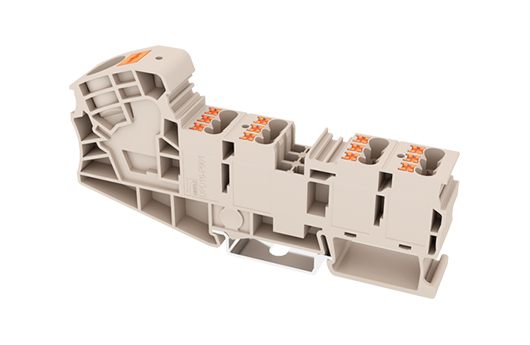

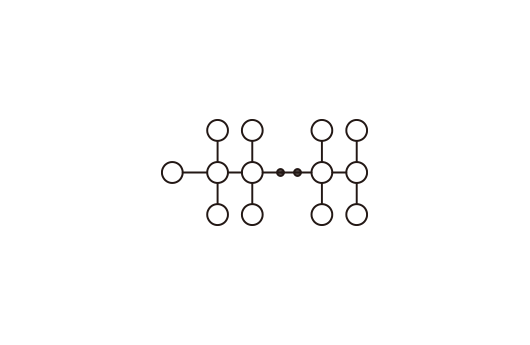

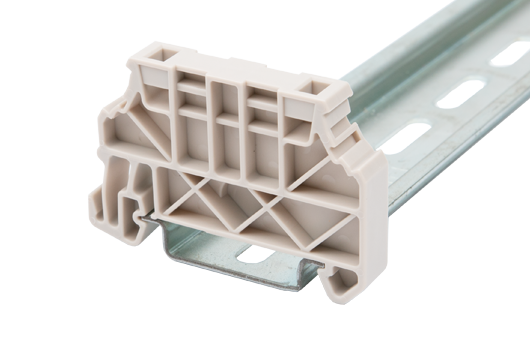

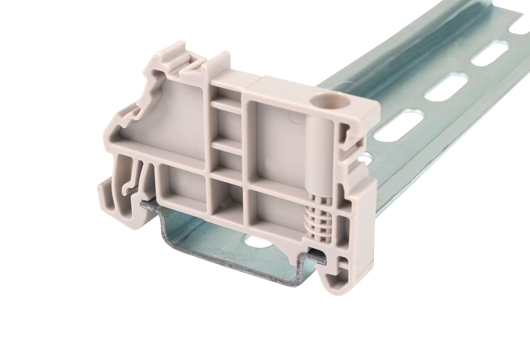

- Potential collective Terminal Block, Push-in Design

- Descrizione completa

- Potential collective Terminal Block, Push-in Design, Width:15.30mm, 600V, 80A

- Categoria

- Potential collective Terminal Block

- Colore

- Beige (default)

- Metodo di connessione

- Push-in Design

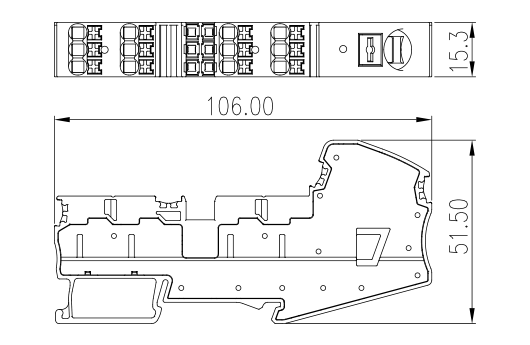

- Lunghezza (mm)

- 108

- Larghezza (mm)

- 15.3

- Altezza (mm)

- 51.5

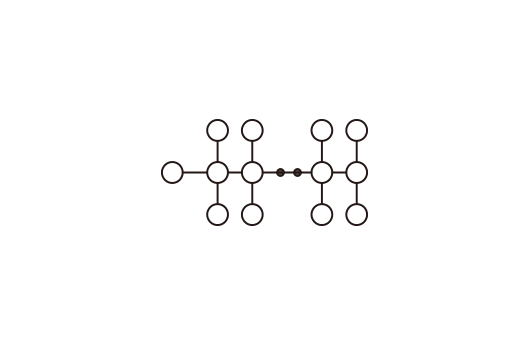

- Livelli

- Single level

- Punti di connessione

- 13

- Informazioni sul materiale

- Informazioni sul materiale

- Dati di connessione - UL

- Ambiente & sicurezza

- Omologazioni UL

- Omologazioni CUL

-

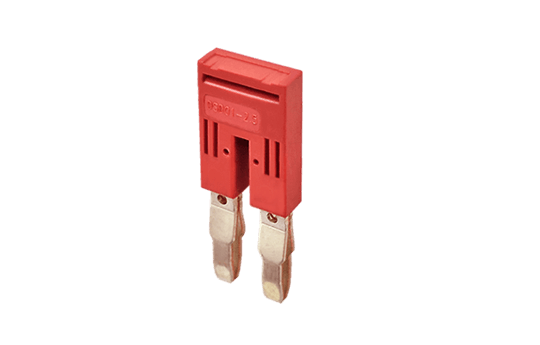

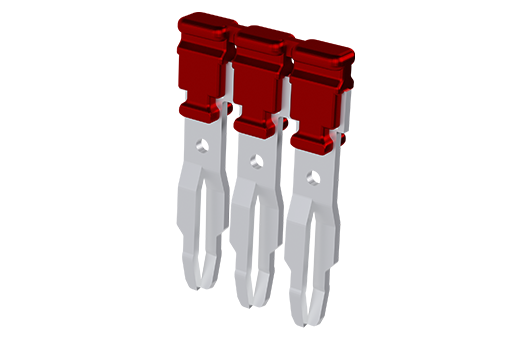

DSD01-2.5XXN

Plug-in bridge For DP2.5N Series, DPP2.5N Series, DP2.5N-3L Series, DP2.5SG Series, DPES2.5, DPES2.5-PE,

DKD10-P001, DPHD10-P001, DPD16-P001, DPD10-P001, DPH2.5 Series,

DPPES2.5, DPPES2.5-PE,

AK2.5 Series, AKK2.5, AKK2.5-D01, AKK2.5-D02, AKK2.5-D03, AKK2.5-D04, AKK2.5-PV

Red color.

Using UL94-V0 class of insulation material. - Add

-

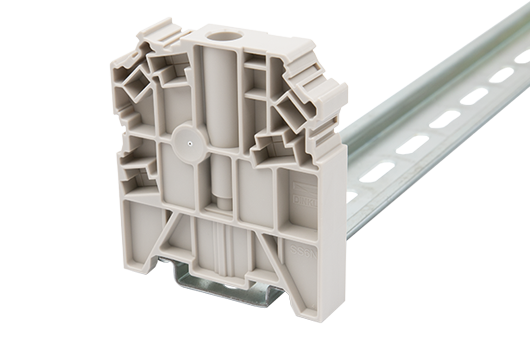

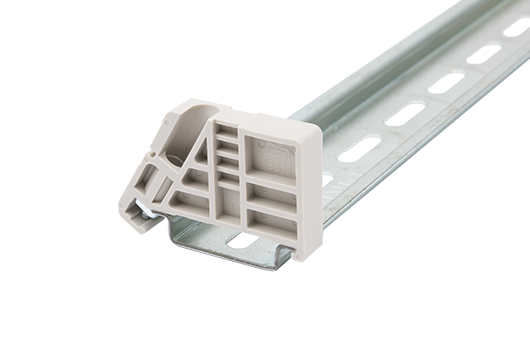

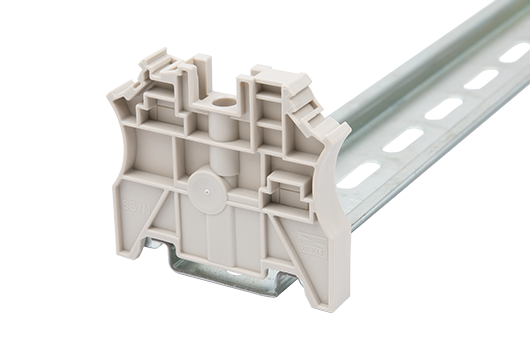

SS6N

End Bracket For TS-35, TS-35/15 rails.

Beige color.

Using UL94-V0 class of insulation material. - Add

-

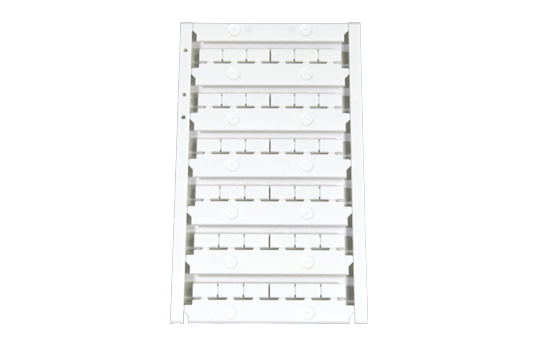

TM45LW

Marking Label For

BEST APPLICATION:

DP10, DP10-PE, DP10-TN, DP10-TN-PE, DKD10-P001, DPHD10-P001, DPH10 Series, AK10, AK10-PE, AK10-TN, AK10-TN-PE

AVAILABLE APPLICATION:

DP16, DP16-PE, DP16-TN, DP16-TN-PE, DPH16 Series, AK16, AK16-PE, AK16-TN, AK35, DPD10-P001, DPD16-P001, DK10-TF, DK10-TFA

White color.

Using UL94-V0 class of insulation material. - Add

-

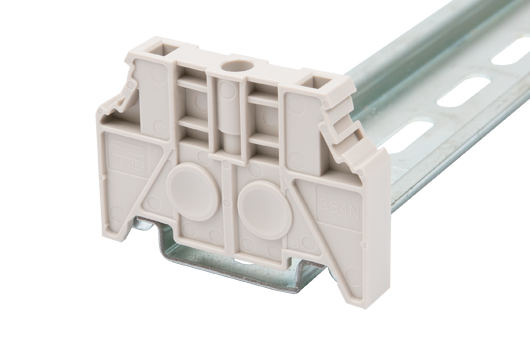

SS11

End Bracket For TS-35, TS-35/15 rails.

Beige color.

Using UL94-V0 class of insulation material. - Add

-

TS-35

DIN-Rail For DP / DK..N / DK.. / AK / DKB / DKU.. /DKM.. series.

Material is iron.

Length of 1000mm / 2000mm. - Add

-

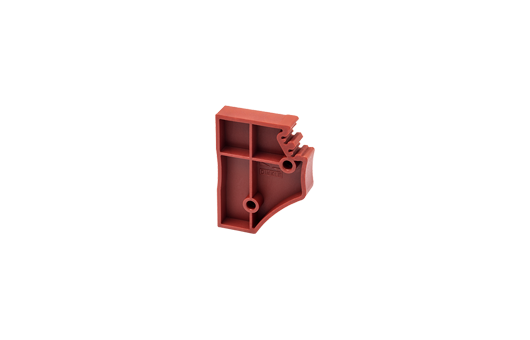

0208-E001

Spacer For DPH2.5 Series, DP2.5N Series, DPP2.5N Series, DPD10-P001, DKD10-P001, DPHD10-P001, DPD16-P001, DP2.5SG, DP2.5SG-L24*, DP2.5SGT, DP2.5SGT-L24*,

DP2.5SG, DP2.5SG-L24*, DP2.5SGR, DP2.5SGR-L24*, DP2.5SGRT, DP2.5SGRT-L24*, DPES2.5, DPPES2.5, DPES2.5-PE, DPPES2.5-PE, DP2.5N-T, AK2.5 Series

Red color.

Using UL94-V0 class of insulation material. - Add

-

TS-35/15

DIN-Rail For DK / DK-PE series.

Material is iron.

Length of 1000mm / 2000mm. - Add

-

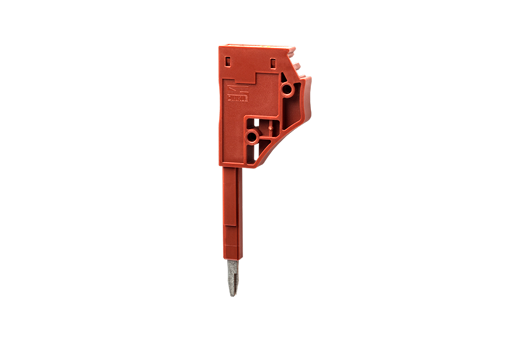

0208-T001

Test Plug For

DPH2.5 Series, DP2.5N Series, DPP2.5N Series, DPD10-P001, DKD10-P001, DPHD10-P001, DPD16-P001, DP2.5SG, DP2.5SG-L24*, DP2.5SGT, DP2.5SGT-L24*, DP2.5SG, DP2.5SG-L24*, DP2.5SGR, DP2.5SGR-L24*, DP2.5SGRT, DP2.5SGRT-L24*, DPES2.5, DPPES2.5, DPES2.5-PE, DPPES2.5-PE, DP2.5N-T, AK2.5 Series

Red color.

Using UL94-V0 class of insulation material. - Add

-

TS-35C

DIN rail end cap For TS-35 rail.

Black color.

Using UL94-V2 class of insulation material. - Add

-

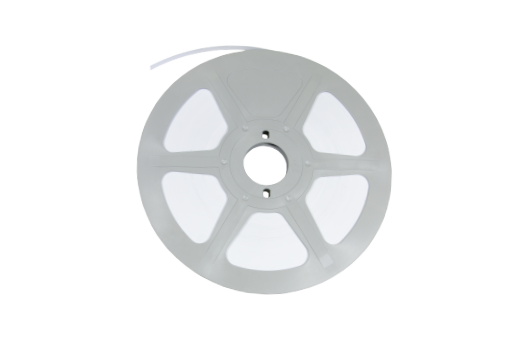

TM-R100

Continuous Flat Marking Labels - Add

-

DSD03-1.5/2.5

Plug-in bridge For DP1.5N Series, DP2.5N Series, DPD10-P001, DPD16-P001, DKD10-P001, DPHD10-P001

Red color.

Using UL94-V0 class of insulation material. - Add

-

DSD06-2.5XXXT

Plug-in bridge For DP2.5N Series, DPP2.5N Series, DP2.5N-3L Series, DP2.5SG Series, DPES2.5 Series,

DPD10-P001, DKD10-P001, DPHD10-P001, DPD16-P001, DPH2.5 Series,

AK2.5 Series, AKK2.5 Series, DPPES2.5, DK2.5L-3L

Red color.

Using UL94-V0 class of insulation material. - Add

-

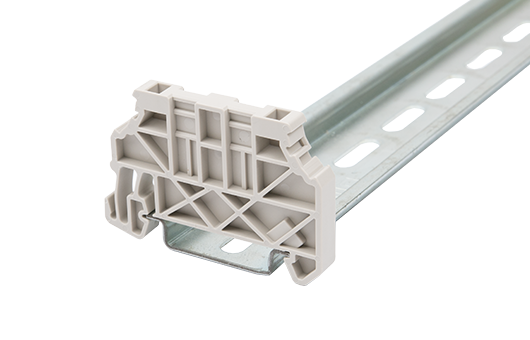

SS7N

End Bracket For TS-35, TS-35/15 rails.

Beige color.

Using UL94-V0 class of insulation material. - Add

-

SS4N

End Bracket For TS-35, TS-35/15 rails.

Beige color.

Using UL94-V0 class of insulation material. - Add

-

SS13

End Bracket For TS-35, TS-35/15 rails.

Beige color.

Using UL94-V0 class of insulation material. - Add

-

DSD03-2.5/6

Plug-in bridge For DP2.5N Series, DP6N Series, DKD35-P001, DKD35-P002, DPD10-P001, DPD16-P001, DKD10-P001, DPHD10-P001

Red color.

Using UL94-V0 class of insulation material. - Add

-

SS5N

End Bracket For TS-35, TS-35/15 rails.

Beige color.

Using UL94-V0 class of insulation material. - Add

-

SS2N

End Bracket For TS-35, TS-35/15 rails.

Beige color.

Using UL94-V0 class of insulation material. - Add

The web catalog is for reference only. Dinkle remains the right of product modification and engineering change of the design. The final product is made according to engineering drawing.